HEBEI PENGXIN PIPELINE EQUIPMENT GROUP CO.,LTD.. was established in the early 1990s, is located in China elbow

pipe capital "mengcun" golden hinterland New hope. Here north of

Beijing and Tianjin, south of Jinan, east Huanghua port, excellent

location, ease of access and the unique economic environment for

the development of the company provides unlimited opportunities.

After nearly two decades of hard business, Hebei Peng Xin Pipeline

Group Ltd. has now developed into a set of tube production, steel

logistics, sales and export as one of the group of companies. Which

owns Hebei Peng Xin Pipe Group Co., Ltd. Hebei Peng Xin Xin Ding

Pipe Group Co., Ltd., Hebei Peng Xin Hua Tuo High Pressure Pipe

Group Co., Ltd., Hebei Xin Peng Bo Tao Group Pipe Manufacturing

Co., four large-scale companies.

Group covers an area 66,600 square meters, the total assets of 318

million yuan, registered capital of 1.0188 billion yuan, annual

production of 30,000 tons pipe fittings, pipe throughput of nearly

ten million tons. The company currently employs 628 people,

including engineers, economists, accountants 128 people. Widespread

branches and offices in major cities in the country, while the

company also has independent export right, the products are

exported to Europe, America, Southeast Asia, Russia and other

countries and regions.

Laid a strong foundation for the development Peng Xin Group, the

Group has 5,000 tons of press, large heat treatment furnace, a

large IF pushing machine, a large bending machine, beveling

machine, sawing machine, lathe, drill press, tee cold extrusion

machine, plywood hammer, vertical lathe, large sandblasting

machines and other related facilities 316 sets. Has advanced

physical and chemical metallurgical, nondestructive testing,

material testing equipment more than 40 sets. And has the world's

most advanced metallic materials direct reading spectrometer,

employing all the national and provincial authorities to obtain

recognized qualifications, and in strict accordance with the

company's quality assurance system for production traceability.

After years of hard work group company has passed the ISO9001

international quality system certification, ISO14001 environmental

management system certification, OHSAS18001 occupational health and

safety management system certification most authoritative industry

certification.

Quality determines survival, the details determine success or

failure. Customer satisfaction for the purpose of quality concept,

created Peng Xin Group's quality and strength.

Peng Xin Group uphold integrity first, create business

opportunities business philosophy. Depending on the product quality

and Honor for the group life, years of spot check inspection Peng

Xin Group's products are always 100% qualified.

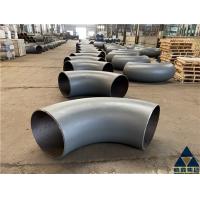

Our main products are electricity, chemical equipment, carbon

steel, alloy steel, stainless steel, X-class series and a variety

of materials elbows, bends, reducers, tees, crosses, head, flange,

bearing plug-in, hangers and other pipeline products. Company

carbon steel, alloy steel, stainless steel and other wall

thickness, size pipe.

Peng Xin Group is the large seamless steel pipe, straight seam

steel pipe, spiral steel pipe, steel pipe logistics base, annual

inventory of 38,000 tons or more. Operating Chengdu Steel, Shanghai

Baosteel, Tianjin big seamless, Jiangsu Chengde, Longchuan steel

mills, Shandong giant, Steel, Anshan Iron and Steel and the United

States, Japan, Germany, Italy and other countries products. And to

Panzhihua, Chengdu Seamless Steel Tube Plant, Hengyang Valin Steel

Tube Co., Ltd., Jiangsu Chengde Steel Tube Co., Ltd. distributor in

North China. Simultaneously and professional production 300000,

600000, 1000000 subcritical, supercritical, ultra-supercritical,

thermoelectric four pipes and pipe factory piping.

Group products are mainly used in petroleum, chemical, natural gas,

nuclear power, thermal power, metallurgy, heat pipe, shipbuilding,

construction and other industries. With Datang, Huaneng, Huadian,

Guodian, China National Petroleum Corporation, China National

Offshore Oil Corporation, rings technology into the Engineering

Company, Saiding engineering company, China Lu engineering company,

Sinochem Second Construction, Chongqing Chemical Medical Group,

Xiamen Xianglu Group, Xinjiang Guinness company, chemical and

Thailand, sky, Lu Tien-oriented, Plum MSG, Ershisanye, Shandong Sea

Chemical Yongxin petrochemical, large stone technology, Chen Hung

chemicals, Wanhua Group etc. has always been a good cooperation.

Peng Xin is its distinctive brand positioning, three-dimensional

marketing strategies in the industry leading the way.

Group Company has obtained API, CE, ASME and other international

and national certification issued by the General Administration of

Quality Supervision, Inspection and China special equipment

manufacturing license, the State Power Corporation power plant

parts supply network member factory, Hebei Boiler and Pressure

Vessel Supervision, Inspection and Supervision, Inspection Unit ,

China National Petroleum Corporation supplies network member unit

of China National Offshore Oil Corporation qualified suppliers,

Datang International Network Supplier Membership materials, China

Huadian Corporation tendering and procurement network provider

group-level member of "China metal materials distribution industry

leader ", Hebei Province, taxes hero and many other honors

Challenges facing the industry, Peng Xin Group, adhering to the

essence Xeon technology, the service flawless reputation to really

sincere business philosophy, and constantly introduce new

technologies, develop new projects and seek new areas. In the

future, Peng Xin people are to unity, progressive attitude, being

in the forefront of pipeline equipment industry to do the industry

leader position leading international brand.